We provide programming and troubleshooting support for most brands and models of PLCs and HMIs. If you are having problems with a machine that is controlled by a PLC, we can help get it back up and running quickly. We can make modifications to existing PLC and HMI applications and also upgrade systems.

We provide programming and troubleshooting support for most brands and models of PLCs and HMIs. If you are having problems with a machine that is controlled by a PLC, we can help get it back up and running quickly. We can make modifications to existing PLC and HMI applications and also upgrade systems.

We are located north of Seattle and provide PLC technical support to customers in the greater Seattle area as well as throughout Washingon state.

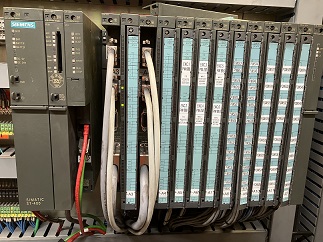

Here are some of the PLC brands and models that we work with:

● Siemens S5 and S7 PLCs including 95U, 100U, 102U, 115U,

135U, 155U, S7-200, S7-300, S7-400, S7-1200 and LOGO

● Texas Instruments TI505 including TI545 and TI555

● Allen-Bradley SLC 500, MicroLogix and ControlLogix

● AEG, Aromat, Automation Direct/Koyo DirectLogic DirectSoft,

GE-Fanuc, Mitsubishi, Modicon Telemecanique, Moeller,

Panasonic NAiS, Omron SYSMAC, SattCon, Square D, Toshiba

and Wago

Other services that we provide include:

Other services that we provide include:● Design, modification and upgrade of

Wonderware Intouch, iFix, Fix32, Beijer,

Citect,Maple Systems, Exor UniOP,

Factorylink and Siemens OP7, OP15 etc.

HMI applications

● Programming of Keyence and Banner

Safety Laser Scanners and PLCs

● Support for ABB, Control Techniques, KEB, Lenze, Leroy Somer

Unidrive and Schneider Altivar VFD drives

● Devicenet, Profibus and Modbus troubleshooting